No products in the cart.

Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 1

Home Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 1

- Home

- Resource Hub

- Millennium Blog

- Pulling vs. Blowing Fiber: A Beginner’s Guide – Part 1

Pulling vs. Blowing Fiber: A Beginner's Guide - Part 1

Start Connecting America with Fiber

From working at home, participating in remote learning, attending virtual healthcare visits, and enjoying home entertainment, the demand for reliable, high-speed internet has exponentially increased since the beginning of the pandemic. Realizing its necessity in everyday life and the glaring digital divide, there has been a boom in economic packages to help connect all Americans with fast, reliable internet. One of the best ways to build a broadband network is with fiber optic cable.

When it comes to efficient fiber deployments, having a crew that is well-trained in either pulling fiber or blowing fiber is essential. But stepping back, how do you know if you should focus on pulling fiber or blowing fiber? In this 3-part series: “A Beginner’s Guide to Pulling vs. Blowing Fiber,” we’ll explore each fiber deployment method, how to choose the best method for your project, and offer videos and tips to maximize your crew’s efficiency.

Pulling Fiber Basics

Pulling fiber is when fiber optic cable is attached to pre-installed pull tape, to be drawn, manually or mechanically, through a run of conduit.

Considerations impacting pulling success:

- Type of cable and conduit

- Temperature

- Terrain elevation changes

- Straightness of the run

These are some of the factors affecting how far you can pull fiber through the duct. When pulling, there is potential for cable damage from friction as the fiber moves through the duct. This damage can cause fiber strands to break or result in high loss within the network. Because you want to protect network quality, pulling fiber is best for fairly straight runs over short distances of a few hundred feet. Since fiber pulling is the most traditional and familiar fiber deployment method, finding experienced pullers tends to be less challenging.

Pulling Fiber: Am I doing it right?

Follow these steps to increase your fiber pulling efficiency. Pulling fiber begins by proofing your duct and preparing it for pull tape installation. Proofing your duct clears any obstructions that may damage your fiber or hinder the pulling process. There should be at least one person on the puller side (Side A) running the equipment and one or two people on the opposite side (Side B) to take the fiber off the reel and feed it into the conduit.

STEP 1

On Side A, where the fiber deployment process begins, use a duct rodder and push it completely through to Side B to proof the duct. If it hits an obstruction (or multiple obstructions), the duct needs to be cleared before the pull can continue.

STEP 2

On Side B, attach pull tape to the rodder, and then pull the rodder back to Side A. Pull tape comes in a variety of strengths, and which one you choose depends on the type of fiber you’re using. Some conduit comes with pre-installed pull tape, saving this step, but it is always recommended to proof the run before fiber deployment.

STEP 3

On Side A, you’ll now attach the pull tape to the fiber optic cable. You may choose to use a pulling grip on the fiber for a stronger hold. The fiber/pulling grip is attached to the pull tape at Side A using a swivel so each can move independently and prevent twisting that may cause damage. It’s important to note that the pull should not exceed the fiber manufacturer’s tensile-load limit as it can compromise the fiber and its usage life.

Best Practices for Pulling Fiber on Short Runs

There are then several ways to begin pulling the fiber through the duct to Side B. If the run is short and straight enough, it can be done manually with one’s hands. However, most fiber pulls are too long to be pulled by hand. That’s when you would need a capstan and a capstan wheel mounted on the ground or a trailer with a hydraulic power pack and foot pedal.

Best Practices for Pulling Fiber on Longer Runs

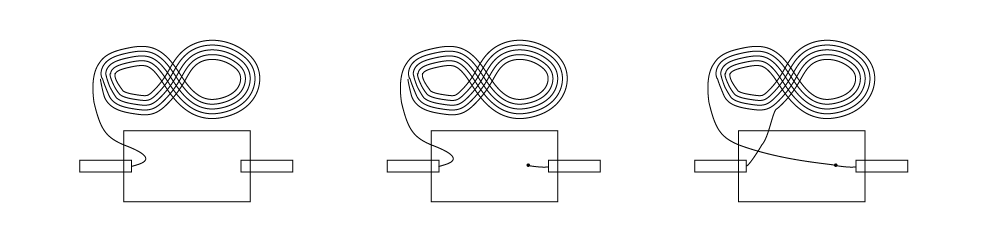

If performing a longer pull, you may need to use an additional fiber puller at intermediate points. If doing so, the fiber should be placed in a figure 8 pattern, following its bend radius, before it is pulled into the next duct run. When placing your figure 8 pattern, the end of the cable should be placed on the ground, and it may be helpful to have a tarp underneath to keep it clean. This helps to ensure a smooth pull by preventing twisting and debris from getting into the duct run.

Why use a fiber puller?

One benefit to using a puller is that the capstan wheel can pull different-sized fibers. So, while your pull tape strength is dependent on fiber size, your capstan wheel is not and can be used for multiple fiber sizes. However, using a larger wheel can help increase your pulling speed and efficiency.

No matter what method is used to pull the fiber, pulling lube should always be used to reduce friction. Once your fiber is pulled through the conduit, it is recommended that you cut off a large section (about 10 feet for a long run) from the side that was attached to the pull tape. This will help remove any fiber that was stretched or damaged throughout the pulling process.

What Fiber Pulling Equipment to Use:

- We recommend the GMP Sidewinder Puller.

- Plus, don’t forget the accessories – Duct Rodders.

This is Part 1 of our 3-part series: “Pulling vs. Blowing Fiber: A Beginner’s Guide.” For more information and tips, check out Part 2 | Part 3

If you have any questions, contact a Millennium Rentals & Leasing Expert.

- Feasibility Studies & Network Design Plans

- Financing & Grants

- Project Resource Management

- Material Supply & Logistical Planning

- Equipment Leasing & Rentals