No products in the cart.

The Importance of Proper Fiber Optic Cleaning and Inspection

Home The Importance of Proper Fiber Optic Cleaning and Inspection

- Home

- Resource Hub

- Millennium Blog

- The Importance of Proper Fiber Optic Cleaning and Inspection

The Backbone of the Broadband Infrastructure

Over the years, fiber optic cable has become the backbone of the broadband infrastructure world, pushing traditional coaxial and category cable to the side as network owners move more towards Fiber To The Home (FTTH) architectures. Traditional cable made from copper degrades over time and can allow for interruptions in the signal; however, fiber is made up of extremely thin strands of glass that have proven to be the most reliable, future-proof medium to transmit enormous amounts of data over long distances bringing high-speed internet to end-users.

As funding for broadband implementation becomes more readily available and the demand for fiber rapidly increases, more and more independent service providers, municipalities, and contractors have become immersed in the telecommunications world. With all of the emerging players to the fiber game, we have identified the need to clarify why implementing proper cleaning and inspection procedures are vital elements for establishing and maintaining a successful network connection.

Keeping it Clean

There is an unlimited variety of environmental conditions that technicians operate within which present the opportunity for dust, debris, oil, water, etc. to hinder the working area. The vast majority of fiber optic network failures stem from either a lack of or improper methods of cleaning. Contaminated fiber links can often lead to potential problems such as back-reflection (signal is diverted back to its source), insertion loss (weakened signal), or a total system shut down. It is imperative that appropriate cleaning measures are used on all connections including ports, splices, end-faces, patch cords, and pigtails for the network to have a high-quality environment to operate within.

Regardless of a cable or connector being reused or directly out of the package, the end faces and ferrules need to be cleaned every single time before mating to make a network connection or for testing purposes. Natural oils from your hands can be transferred to the fiber end faces and inserting and removing a fiber tends to create a small static charge on the ends, which can result in the attraction of airborne dust particles. Fiber caps, which are used to prevent fiber ends from being scratched while not seated in a connector, will collect dirt, oil, and dust, transferring those contaminants to the fiber when used. Caps should still be used when storing or pulling fiber cables, but the ends should be cleaned before inserting them into an interface.

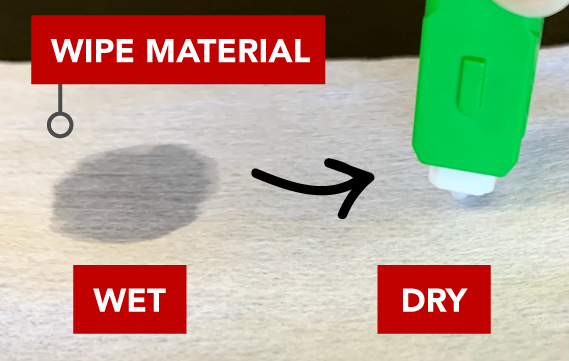

Many common techniques used in fiber optic cleaning give inconsistent results and can promote recontamination. Dry cleaning, cleaning with isopropyl alcohol (IPA) that is less than 99% pure IPA, and wet cleaning of connectors provide poor results. The best fiber optic connector cleaning method is the combination cleaning method. This technique involves using a small amount of solvent on a lint-free wiping material and immediately drying the surface.

The 3 Don’ts of Fiber Optic Cleaning

- Don’t Clean Without Solvent

- Risk Damaging end-face

- Difficult to remove debris and oil

- Creates static charge that attracts debris

- Don’t Clean With Less than 99% Pure IPA

- Not as effective cleaning soils, buffer gels, and oils

- Leaves residue when not followed by dry clean

- Slow evaporation rate

- Don’t Clean With Excessive Solvent

- Results in ferrule flooding

- Wastes product

- Leaves a residue that’s still detectable under a microscope

Try This Instead

The Combination Cleaning Process

- Place a dime-sized drop of solvent on the wipe, and then lightly draw in a straight line from the solvent over the dry wipe, removing the soils and drying the end face in one motion.

- Debris and contamination are moved away from the initial point of contact in a straight line.

- Avoid figure 8 motions and twisting or turning motions, as these can redeposit contaminants or grind debris into the end face.

- Avoid hard-backed surfaces, as they can also grind debris into the end face

View our Selection of Fiber Optic Cleaning Supplies >

Fiber Optic Inspection

The combination of proper cleaning and inspection before making a network connection is one of the most effective strategies to avoiding fiber link failures. Now that you are familiar with proper cleaning protocol, let’s dive deeper into the importance of fiber optic inspection.

Fiber inspection probes and scopes (AKA microscopes) are fast, simple to use tools that give technicians, network managers, IT professionals, and contractors the ability to view the cleanliness of connector end-faces on a microscopic level since the debris that collects on them is not always visible to the naked eye.

Proper Inspection and Cleaning Process

The best strategy for proper inspection is to use a probe or scope to inspect first, if it is clean, move forward and connect it; however, if the connector is dirty then you will need to clean it, reinspect, and connect once your end face passes the inspection. Although some find the inspection stage to be tedious, it is an essential part of building a healthy network. It only takes a few moments to properly inspect fiber end faces. When done correctly and consistently, it can help prevent major issues from happening in the future.

View our Selection of Fiber Optic Inspection Probes and Scopes >