No products in the cart.

Tips for Feeding Pull Tape Without Fiber Damage

Home Tips for Feeding Pull Tape Without Fiber Damage

- Home

- Resource Hub

- Millennium Blog

- Tips for Feeding Pull Tape Without Fiber Damage

Feeding pull tape through conduit is a fundamental step in deploying fiber optic cable. When executed correctly, it’s a straightforward process. However, improper technique can introduce significant risks, including friction, sheath abrasion, and ultimately, costly fiber damage. Protecting the integrity of the fiber cable from the very beginning of the installation process is paramount for network longevity and performance.

Successfully feeding pull tape requires a combination of the right equipment, meticulous preparation, and adherence to proven methodologies. By focusing on preventative measures, installation teams can mitigate the risk of damage and ensure a smooth deployment that avoids costly repairs and project delays. We’re giving our expert tips for feeding pull tape without fiber damage to safeguard your installation and network reliability.

Select the Correct Conduit Size

Proper conduit sizing is the first line of defense against fiber damage during installation. Selecting a conduit in the appropriate size for the fiber optic cable is critical. An oversized conduit may seem like an easy choice, but it can allow the pull tape and cable to twist and overlap, increasing friction. Conversely, a conduit that is too small creates excessive friction and pressure on the cable jacket, substantially raising the risk of abrasion and damage.

Industry standards, such as those provided by the Telecommunications Industry Association (TIA), recommend a maximum fill ratio of 40 – 60 percent for a single cable. This ratio ensures there is adequate space for the cable to pull without unnecessary force, while also leaving room for future network expansion.

Inspect and Clean the Conduit Thoroughly

Before any pull tape or cable enters the conduit, a thorough inspection and cleaning of the pathway are mandatory. Debris, dirt, moisture, or obstructions left inside the conduit can create significant friction points. As the pull tape is fed through, it can drag this debris along, creating abrasive conditions that may damage the tape itself or, more critically, the fiber cable’s outer jacket during the subsequent pull.

Use a mandrel or a duct brush to clear the conduit of any foreign materials. For longer runs, blowing a foam carrier (a piston or mouse) through the duct with compressed air can verify that the path is clear and remove smaller particles and moisture. This simple preparatory step is one of the most effective ways to reduce pulling tension and prevent sheath damage.

Use a Blower for Long-Distance Installations

For extensive conduit runs, manually pushing pull tape is inefficient and increases the risk of the tape folding or twisting. A specialized cable blowing machine is the superior method for these applications. This equipment uses a high volume of compressed air to float the pull tape through the conduit, significantly reducing friction.

The blower propels the tape forward on a cushion of air, minimizing contact with the conduit walls. This technique is substantially safer and faster for the eventual fiber pull, as it ensures the pull tape is laid flat and straight within the duct. Investing in or renting the proper blowing equipment is a crucial step for maintaining efficiency and safety on large-scale fiber projects.

Lubricate the Conduit Adequately

Cable pulling lubricants are essential for reducing the coefficient of friction between the pull tape, the cable, and the conduit walls. Applying a high-quality, fiber-optic-specific lubricant decreases the required pulling force by up to 80 percent. This reduction in tension directly translates to a lower risk of exceeding the cable’s maximum tensile strength and causing irreparable damage.

Apply the lubricant generously and evenly as the pull tape feeds the conduit. For long pulls, it is also advisable to apply lubricant to the fiber cable itself as it enters the duct. Make sure the chosen lubricant is compatible with the cable jacket material and will not degrade it over time.

Maintain a Consistent Feeding Speed

When feeding the pull tape, whether by hand or with a blower, maintaining a steady and controlled speed is crucial. Erratic or excessively fast feeding can cause the tape to slap against the conduit walls, twist, or bunch up, creating knots and friction points. A slow and consistent pace allows the tape to lay flat and follow the contours of the conduit smoothly.

If using a blower, regulate the air pressure to achieve a consistent feed rate. If feeding by hand, use a smooth, continuous motion. Rushing this stage of the process is a common mistake that can lead to complications during the actual cable pull.

Avoid Twisting the Pull Tape

Twisted pull tape can act like a file, abrading the cable sheath as you pull it through the conduit. A flat, untwisted tape provides a smooth surface for the cable to ride on. To prevent twisting, make sure the tape is paid out from its spool or coil without introducing any torsion.

Using a dispenser or reel stand that allows the spool to rotate freely is the best way to prevent twists from forming. If you’re using a detectable pull tape rope, its rounded construction can mitigate some twisting issues, but careful handling remains essential. Periodically check the tape as it enters the conduit to ensure it remains flat.

Use a Leader or Carrier

For enhanced efficiency, especially when using a blowing system, attach a lightweight leader or foam carrier to the end of the pull tape. This small, aerodynamic object guides the tape through the conduit and navigates bends more easily.

- The carrier catches the airflow from the blower, effectively pulling the tape behind it.

- It helps the tape float more effectively, reducing friction.

- It provides a clear visual and physical indicator when the tape reaches the other end of the conduit.

Monitor Tension During the Pull

While this tip relates more to the subsequent cable pull, it’s a direct result of how well the pull tape was fed. During the actual fiber installation, use a dynamometer or tension-monitoring device. This tool provides real-time feedback on the pulling force being exerted on the cable.

By feeding the pull tape correctly and using ample lubrication, you will have already minimized the potential for high tension. Monitoring the tension during the pull serves as a final quality control check, ensuring that the cable does not exceed its maximum rated tensile load. If tension begins to spike, stop the pull immediately and investigate the cause.

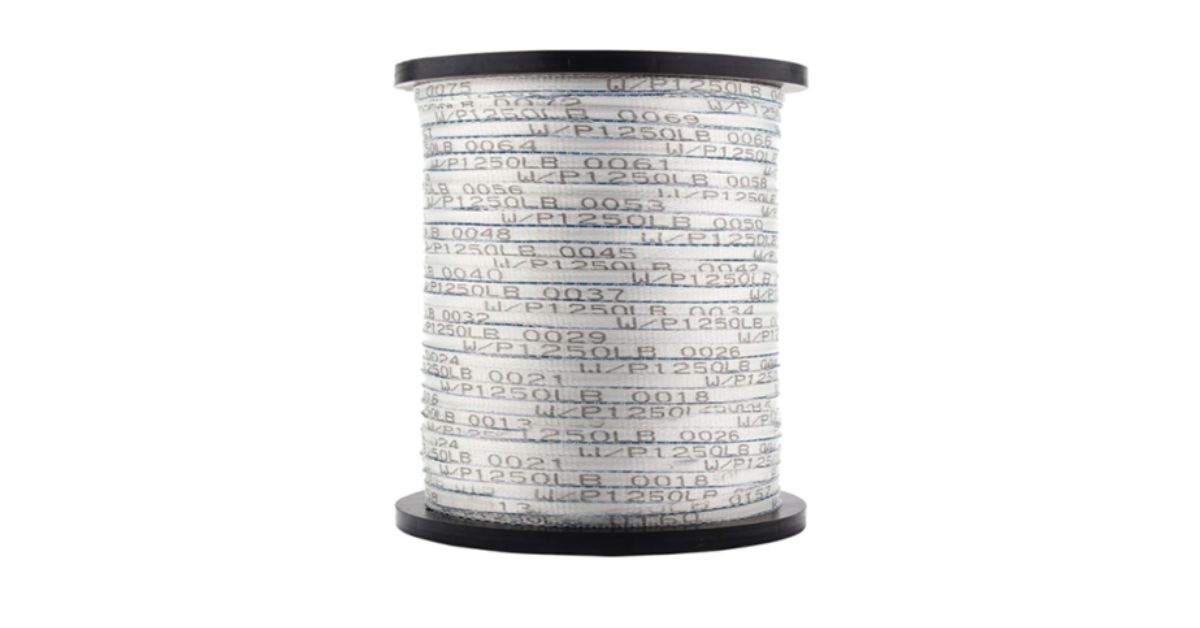

Millennium provides custom solutions, including a complete range of pull tape. Shop the complete collection of pull tape or partner with one of our trusted team members to ensure the right fit and to avoid fiber damage.