No products in the cart.

8 Ways To Improve Cable Lashing for Aerial Fiber

Home 8 Ways To Improve Cable Lashing for Aerial Fiber

- Home

- Resource Hub

- Millennium Blog

- 8 Ways To Improve Cable Lashing for Aerial Fiber

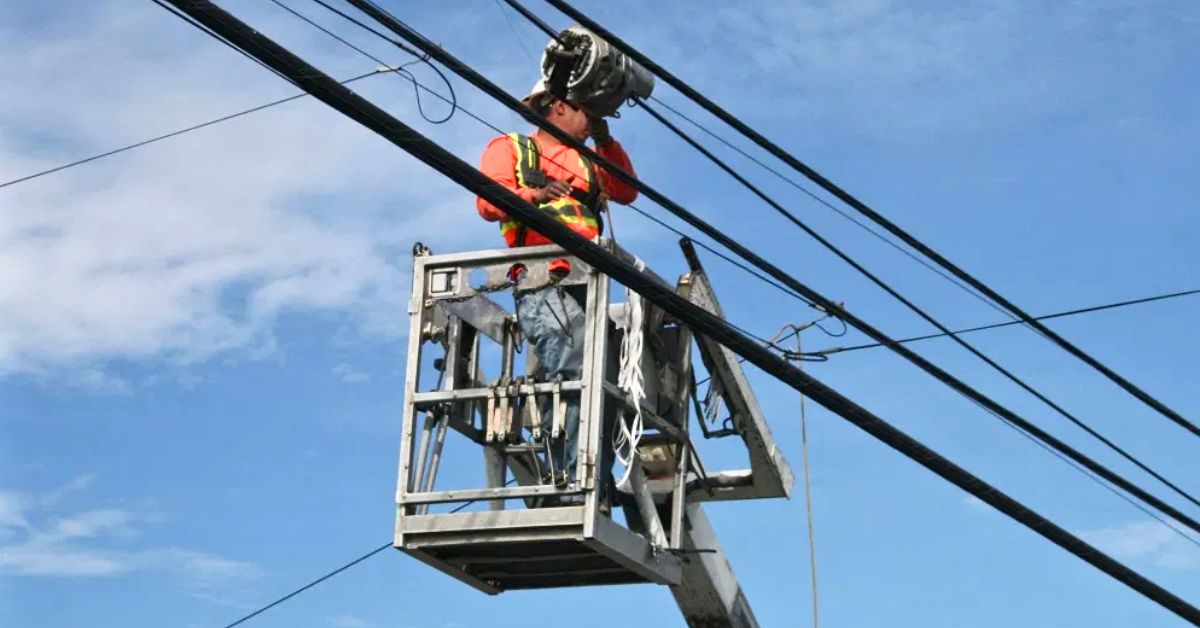

Cable lashing is the process of binding a telecommunications cable, such as a fiber optic cable, to a supporting steel strand. This technique is fundamental for aerial fiber optic network deployment, providing stability and protection against environmental stressors. Executing this process with precision is critical for the long-term reliability and performance of a network. Ineffective lashing can lead to cable sagging, damage, and costly service interruptions. By refining your lashing procedures, you can enhance the durability of your aerial plant and secure your investment.

This detailed guide discusses eight actionable strategies to improve cable lashing for aerial fiber operations. From equipment selection to personnel training, each step will elevate the quality of your installations. Implementing these best practices will mitigate risks and optimize the performance and longevity of your network infrastructure. Let’s get into the details.

1. Use Quality Lashing Equipment

The foundation of any successful aerial installation is the equipment you use. Employing high-quality, well-maintained cable lashers is nonnegotiable for achieving secure and durable lashing. Subpar or poorly maintained equipment can lead to inconsistent lashing, incomplete wraps, and even damage to the lashing wire or cable. These issues compromise the structural integrity of the installation from the outset.

Investing in reliable, industry-proven lashers ensures consistent performance, reduces the likelihood of on-site failures, and contributes to a safer working environment. High-quality equipment delivers the precise tension and smooth operation needed to bind the cable securely to the strand, minimizing the risk of future maintenance issues.

2. Select the Appropriate Cable

Proper cable selection is just as important as the equipment used to install it. The fiber optic cable must fit the specific environmental conditions and the physical demands of the aerial route. Factors to consider include the cable’s diameter, weight, and the material of its outer jacket.

A cable that is too heavy for the support strand can cause excessive sagging, while one with an inadequate jacket may degrade prematurely when exposed to UV radiation or extreme temperatures. You must choose a cable that offers the right balance of durability, flexibility, and resistance to environmental factors to guarantee it withstands the test of time.

3. Ensure Correct Lashing Tension

Achieving the correct tension in the lashing wire is a critical skill that directly affects the quality of the installation. If the tension is too loose, the cable will not hold securely against the support strand, leading to sagging and movement that can cause abrasion and damage over time.

Conversely, if the tension is too tight, it can compress the fiber optic cable, potentially causing signal loss or damage to the delicate glass fibers within. Technicians must know how to set and maintain the optimal tension throughout the lashing process. Using lashers with reliable and adjustable tension controls is essential for achieving this balance consistently across every span.

4. Inspect Equipment Regularly

A proactive approach to equipment maintenance is essential for operational excellence and safety. Before each use, technicians should conduct a thorough inspection of the cable lasher and all associated components. This includes checking for wear and tear on the drive wheels, ensuring the wire drum rotates freely, and verifying that all moving parts are properly lubricated. Regular inspections can identify potential problems before they lead to equipment failure in the field, which can cause project delays and safety hazards.

A scheduled maintenance program ensures that your equipment remains in optimal working condition, ready to perform reliably on every job. For organizations managing multiple projects, a cable lasher rental program can provide access to professionally maintained equipment without the long-term capital expense.

5. Train Personnel Adequately

The most advanced equipment is only as effective as the person operating it. Comprehensive training for all technicians is a cornerstone of high-quality aerial fiber deployment. Personnel must be proficient in the operation of the lashing equipment, but also in the underlying principles of proper aerial installation.

Training must cover best practices for route planning, tension techniques, equipment maintenance, and, most importantly, safety procedures. An adequately trained workforce operates more efficiently, produces higher-quality work, and can better identify and mitigate potential issues in the field, ensuring every installation meets your organization’s standards.

6. Plan the Route Carefully

Careful and strategic route planning is a critical preliminary step for any aerial fiber installation. Before any lashing begins, the entire route should be surveyed to identify potential obstacles, such as trees, buildings, or other utility lines. Planning the route to avoid these obstructions minimizes physical stress on the cable and lashing wire.

A well-planned route also accounts for the necessary clearances and the placement of hardware like tangent supports and dead ends. This foresight prevents sharp bends or excessive tension points that could compromise the cable’s integrity and ensures the installation complies with all relevant regulations and safety standards.

7. Adhere to Industry Standards

Your lashing procedures should always align with established industry standards, such as those set by organizations like the Telecommunications Industry Association (TIA) and the National Electrical Safety Code (NESC). These standards provide a framework of best practices developed to ensure the safety, reliability, and interoperability of telecommunications infrastructure.

Adherence demonstrates a commitment to quality and professionalism. Following these guidelines helps you avoid common pitfalls, ensure regulatory compliance, and build a network that is durable and safe for your workers and the public.

8. Monitor Environmental Factors

Environmental conditions can have a significant influence on aerial fiber installations. Factors, such as extreme temperatures, high winds, ice loading, and UV exposure, must be considered during the planning and installation phases. For example, installing cable in very low temperatures can make the materials brittle and more susceptible to damage.

In areas prone to heavy ice or wind, you may need to use stronger support strands and adjust sagging calculations to account for the additional load. Train technicians to recognize how environmental factors can affect the lashing process and take appropriate precautions to ensure secure and lasting installation.

Enhance Your Aerial Fiber Deployments

Improving your cable lashing methods is a direct investment in the long-term health and reliability of your aerial fiber network. By focusing on quality equipment, proper training, and adherence to industry best practices, you can significantly enhance the durability and performance of your installations.

Each of the strategies outlined here provides a clear path to elevating your operational standards. As you implement these improvements, you will build a more resilient network and foster a culture of excellence and safety within your organization. Partner with Millennium for rental programs that suit a wide range of installation types and demands. We provide easy, convenient financing terms to suit install budgets of any size.