No products in the cart.

How To Choose the Right Conduit Type for Fiber Installations

Home How To Choose the Right Conduit Type for Fiber Installations

- Home

- Resource Hub

- Millennium Blog

- How To Choose the Right Conduit Type for Fiber Installations

Selecting the appropriate conduit type forms the foundation of every successful fiber optic installation project. The wrong choice can lead to costly delays, increased maintenance requirements, and potential system failures that compromise network performance. Understanding the technical specifications, environmental factors, and installation requirements will ensure your fiber infrastructure delivers optimal performance for decades.

The conduit serves as the protective pathway for fiber optic cables, shielding them from environmental hazards, physical damage, and interference. Each installation presents unique challenges that demand specific conduit solutions. From underground direct burial applications to aerial installations, choosing the right conduit type for your fiber installation requires careful evaluation of multiple technical and environmental variables.

Understand Environmental Conditions and Their Impact

Environmental factors significantly influence conduit performance and longevity. Temperature variations affect material expansion and contraction rates, while moisture exposure can compromise cable integrity if improper sealing occurs. Underground installations face different challenges than aerial deployments, including soil composition, groundwater levels, and freeze-thaw cycles.

Chemical exposure presents another critical consideration, particularly in industrial environments where corrosive substances may contact the conduit system. Salt exposure in coastal areas accelerates corrosion in metallic conduits, while UV radiation degrades certain polymer materials in outdoor applications.

Seismic activity and ground movement require flexible conduit systems that accommodate structural shifts without damaging enclosed cables. Wind loading affects aerial installations, demanding robust mounting systems and appropriately sized conduits that resist deformation under stress.

Evaluate Installation Method Requirements

Installation methodology affects conduit selection decisions. Direct burial applications require materials that withstand soil pressure and resist root intrusion while maintaining structural integrity over time. Trenching operations demand conduits that handle mechanical stress during installation without compromising protective capabilities.

Horizontal directional drilling (HDD) installations require conduits with specific tensile strength ratings and flexibility characteristics. The conduit must resist pulling forces while navigating curved bore paths without kinking or collapsing. Joint integrity becomes critical in these applications to prevent debris infiltration.

Aerial installations present unique requirements for conduit systems, including wind resistance, thermal expansion accommodation, and support structure compatibility. The conduit must maintain cable protection while allowing for natural movement and thermal cycling.

Assess Cable Capacity and Future Expansion Needs

Proper conduit sizing ensures adequate cable capacity while accommodating future network expansion requirements. Undersized conduits limit upgrade potential and increase installation costs when additional capacity becomes necessary. Oversized conduits waste resources and may not provide adequate cable support.

Standard fill ratios guide conduit selection, with telecommunications applications typically requiring 40 percent maximum fill for single cables and 25 percent for multiple cable installations. These ratios ensure proper airflow, heat dissipation, and installation clearances while maintaining tension within acceptable limits.

Determine Material Properties and Performance Characteristics

Material selection influences conduit performance across various installation environments. High-density polyethylene (HDPE) provides excellent chemical resistance and flexibility, making it suitable for underground installations and HDD applications. The material resists stress cracking and maintains structural integrity across wide temperature ranges.

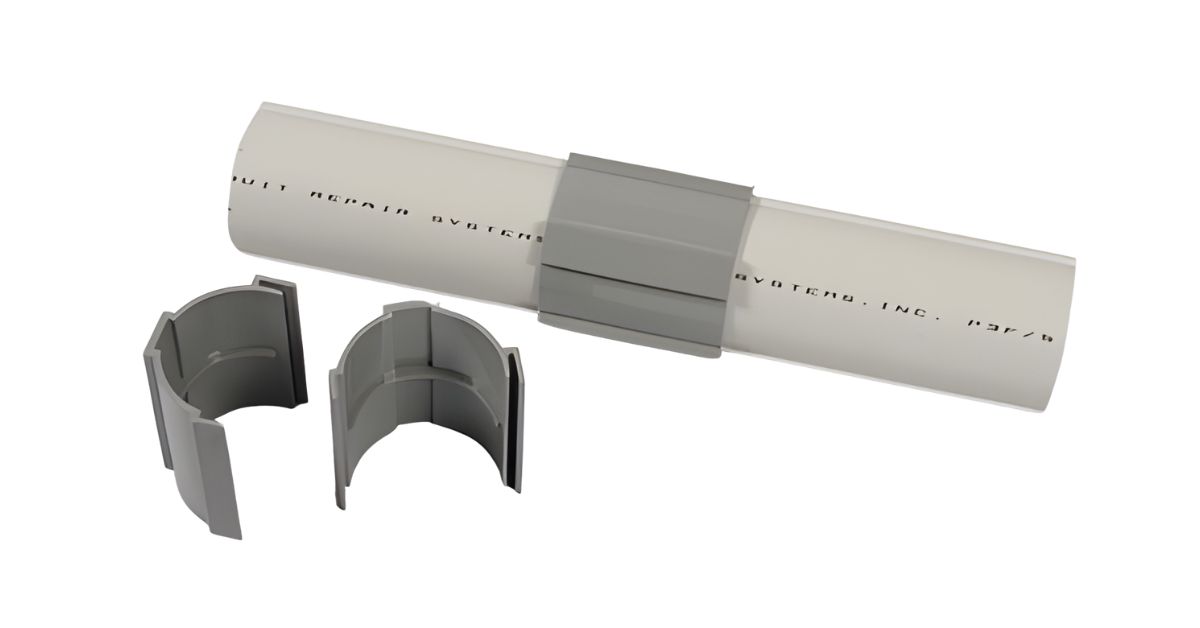

Polyvinyl chloride (PVC) conduits offer cost-effective solutions for many applications, providing good mechanical strength and chemical resistance. However, PVC becomes brittle at low temperatures and may require special considerations in cold climates. Split PVC pipe solutions facilitate cable installation in retrofit applications where continuous conduit runs are impractical.

Consider Installation Depth and Protection Requirements

Installation depth affects conduit selection through load bearing requirements and environmental exposure factors. Shallow installations require conduits with higher crush strength ratings to withstand surface loading from traffic, equipment, and structural foundations.

Deep installations face increased soil pressure and potential groundwater exposure, demanding materials with appropriate pressure ratings and moisture resistance capabilities. Conduit joints must maintain integrity under sustained pressure while preventing water infiltration.

Analyze Pulling Tension and Installation Stress Factors

Cable pulling operations subject conduits to significant mechanical stress that can compromise system integrity if not properly managed. Conduit materials must withstand pulling tensions without deformation while maintaining smooth internal surfaces that minimize cable jacket damage.

Coefficient of friction between cable jackets and conduit materials affects pulling force requirements and installation feasibility. Low-friction conduit interiors reduce pulling tensions and enable longer cable runs without intermediate pulling points.

Examine Joint Systems and Connection Methods

Joint integrity critically impacts conduit system performance and long-term reliability. Mechanical joints must maintain alignment and sealing capabilities under operational stresses while facilitating future access for maintenance or upgrades.

Fusion welding provides superior joint strength and environmental sealing for HDPE conduit systems. Welded joints eliminate potential failure points while creating continuous conduit runs with consistent internal dimensions.

Factor in Maintenance and Accessibility Requirements

Maintenance accessibility affects conduit design and installation planning. Systems requiring frequent cable changes benefit from removable access points and larger conduit sizes that facilitate cable manipulation.

Inspection capabilities enable proactive maintenance and system monitoring. Conduits with integrated access points support fiber optic testing equipment and cable condition assessment without system disruption.

Evaluate Cost Factors and Long-term Value

Initial material costs represent only one component of total conduit system economics. Installation labor, equipment requirements, and long-term maintenance costs can influence project economics and return on investment calculations.

Service life expectations affect material selection decisions and project planning timelines. Higher-quality conduit materials may justify increased initial costs through extended service life and reduced maintenance requirements.

Plan for Regulatory Compliance and Standards

Local building codes and utility regulations establish minimum conduit specifications for different installation types. Compliance requirements affect material selection, installation methods, and maintain documentation standards throughout the project lifecycle.

National electrical codes provide guidance on conduit sizing, installation practices, and safety requirements. These standards ensure compatibility with electrical systems and establish minimum performance criteria for telecommunications applications.

Make the Right Choice for Your Project

Successful conduit selection requires systematic evaluation of all relevant factors affecting system performance and reliability. Technical specifications must align with environmental conditions, installation methods, and operational requirements to achieve optimal results.

Documentation of selection criteria and decision rationale supports future maintenance planning and system expansion activities. Proper record-keeping ensures consistency across multiple project phases and facilitates troubleshooting when issues arise.

The investment in proper conduit selection pays dividends through enhanced system reliability, reduced maintenance costs, and improved expansion capabilities. Take the time to thoroughly analyze your specific requirements and select conduit systems that will support your fiber infrastructure goals for years to come. Reach out to Millennium Broadband for help choosing the right conduit for your next fiber installation. With years of experience and trusted expertise, you’ll be sure to get everything you need.